Bacteria and Reverse Osmosis

Bacteria and Reverse Osmosis – RO

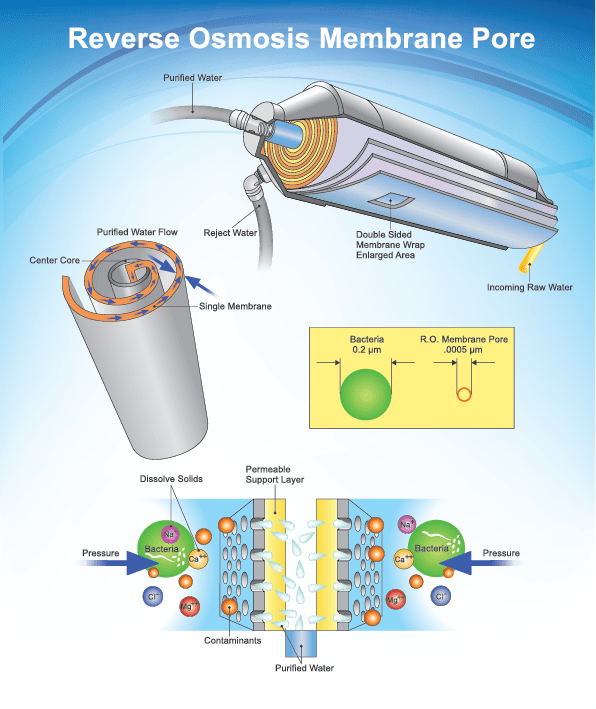

Bacteria and viruses are removed by RO as the pore size of the RO membrane is approximately 0.0005 micron. Ceramic filters by comparison have a pore size of 0.8 microns.

Bacteria and viruses are much larger in size than the pores of the membranes.

Bacteria size is 0.02 – 0.4 micron and viruses are 0.2 – 1.0 micron.

A great analogy I heard was describing the size of the bacteria and viruses as 100 – 2500 times the size of the RO membrane pores.

This is like a whale trying to swim through a net with 1 ” size holes in it.

Contrary to popular belief, RO membranes cannot however guarantee 100% removal of bacteria and viruses.

There is always the possibility in all the square feet of membrane material that there is a small pinprick hole.

That is why membranes are typically rated at 99.9% effective at bacteria and virus removal.

It may be 100% effective or it may not be, depending on the manufacturing process and handling/care during the membrane assembly process.

Many membrane manufacturers make their membrane pockets by hand and this can lead to the introduction of human error.

No RO system should ever be used on microbiologically unsafe water, without sterilization existing before, or after the membrane.

With one of these pinprick holes, bacteria or viruses can pass through, making the water unsafe.

One of these holes could result in bacteria growing through the membrane, fouling it, or causing illness.

A very viable solution is to place a UV sterilizer before or after the RO to ensure safe water.

A UV after the RO is simple, as the pre-treatment requirements for comprar winstrol the UV will already be met as the RO water is so clean, but this will not prevent fouling of the membrane if algae or bacteria grow on the membrane surface blocking the pores.

Biofilm is a slimy, gelatinous material that is secreted by bacteria in order to protect themselves from chemicals and to provide an endless food supply.

This biofilm (slime) can be felt if you place some water in a bucket and let it stand for a few days.

There will be a slime buildup on the inside surfaces of the bucket.

The longer it’s left unchecked the thicker it will grow and the harder it will be to remove.

A combination of bleach/sanitizer is typically used.

This biofilm is quite resistant to removal.

If it is not all removed with strong enough concentrations of sanitizer and detergent, the remaining biofilm can actually grow back much faster and heavier than before as the chemicals serve to aggravate the biofilm and it seeks to repair itself.

If you run a purified drinking water facility you are required to check the amount of biofilm in your system.

This biofilm growth is measured by laboratories using an HPC (Heterotrophic Plate Count) test.

A sample of the water is held at a set temperature for three days and then the number of plates is counted to provide the HPC results. Typically you will be required to keep the plate count below 200.

This can vary by region to be 100 – 500 counts for human consumption so be sure to check with your health authority.

Make sure when presenting samples for testing, that the sample is kept below 10C for the trip to the lab.

If the sample arrives and it is warmer, then false readings occur as well as higher results than are actually in your system.

The Water Filter Solution Guy has significant experience in managing and controlling biofilm.

If you are experiencing problems with elevated biofilm (High HPC counts) feel free to email me from the Contact US page and I will assist you in finding solutions.

This course shows you how to overcome paralyzing fear and pursue your life's dreams. Conquer insecurity and enhance your performance in every area of life.

This course shows you how to overcome paralyzing fear and pursue your life's dreams. Conquer insecurity and enhance your performance in every area of life.